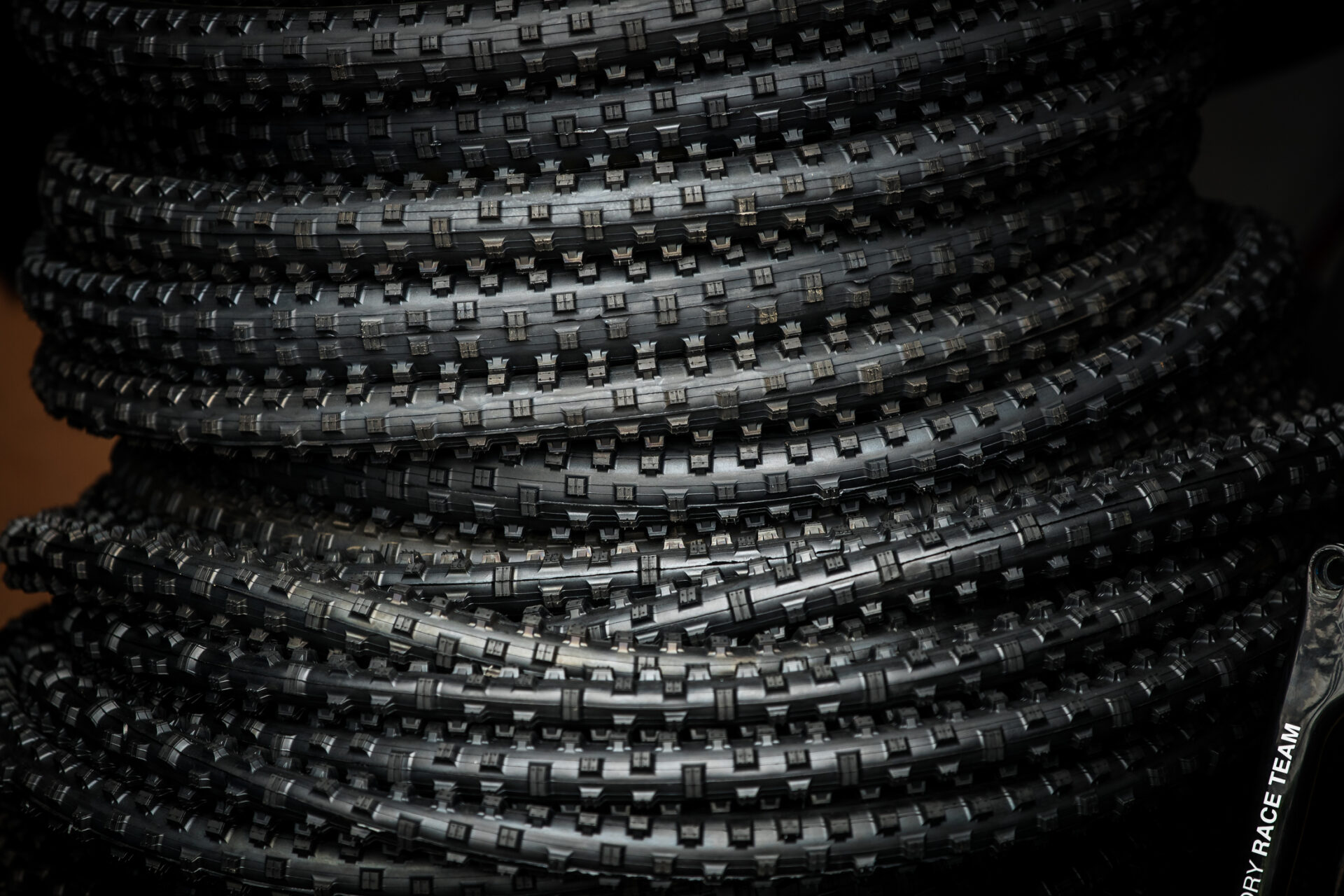

INTRODUCING TEAM SPEC TIRES & ASPEN ST

Learn More

Experience the Smooth Ride and Modern Style

with the RAZR HT

Our Latest Flagship Highway Terrain Tire!

RAZR HT

World Champion-level Performance

Available to all

Dealer Locator